Introduction

Factory breakdowns are costly. A single unexpected equipment failure can halt production, delay orders, and result in huge financial losses. Globally, unplanned downtime is estimated to cost manufacturers over $1.4 trillion annually. But thanks to advancements in artificial intelligence (AI) and robotics, factories are finding smarter ways to stay running smoothly.

AI and robotics are being used not just for automation but also for predictive maintenance, helping factories detect potential issues before they turn into expensive failures.

What is Predictive Maintenance?

Predictive maintenance uses AI algorithms and sensor data to monitor machines in real time. These systems can identify abnormal patterns—like vibrations, temperature spikes, or strange noises—that indicate a machine might soon break down.

Instead of waiting for failure or relying on fixed service intervals, predictive maintenance allows factories to perform repairs only when needed, based on actual data.

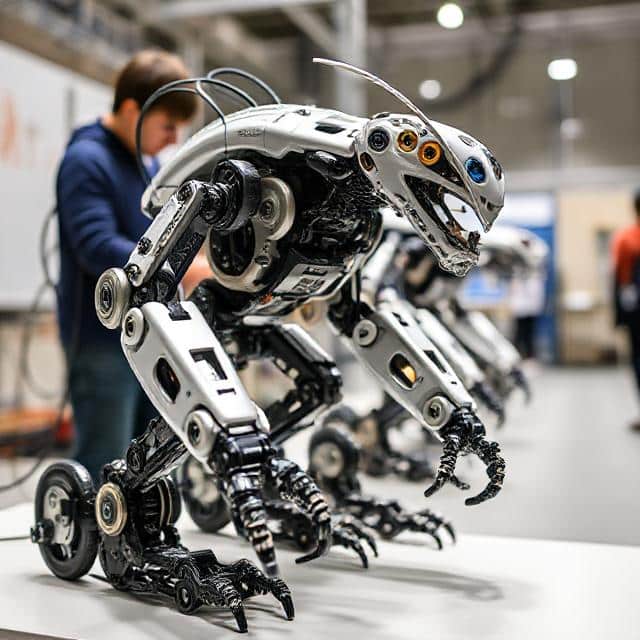

Role of Robotics in Maintenance

Robots now play a key role in both monitoring and maintenance tasks:

- Inspection Drones and Crawlers: These robotic devices can inspect hard-to-reach places (like pipelines or turbines) without shutting down equipment.

- Ultrasound and Laser Sensors: Mounted on robotic arms, these tools scan machinery surfaces for cracks, corrosion, or misalignments.

- Maintenance Bots: Some robots are designed to perform basic repair tasks like tightening bolts or replacing parts.

These robots collect data and send it to AI platforms that analyze performance and predict possible breakdowns.

Benefits of AI and Robotics in Preventive Maintenance

- Reduced Downtime: Predicting issues early helps avoid unexpected shutdowns.

- Cost Savings: Maintenance is performed only when necessary, reducing waste and saving on repairs.

- Extended Equipment Life: Machines last longer when they are properly maintained.

- Improved Safety: Robots reduce the need for humans to enter dangerous areas.

- Higher Efficiency: AI helps schedule maintenance without disrupting production.

Real-World Examples

- Aquant: Uses AI to help companies like Coca-Cola and Johnson Controls predict machine failures and optimize service.

- Gecko Robotics: Builds robots that inspect power plants, refineries, and factories using sensors and AI to detect critical issues.

These technologies are already being adopted by global manufacturers, reducing downtime and increasing reliability.

Conclusion

AI and robotics are reshaping industrial maintenance. With predictive capabilities, real-time monitoring, and smart automation, factories can avoid costly breakdowns, enhance safety, and run more efficiently. As technology advances, predictive maintenance will become standard practice in every smart factory around the world.

Related Reading.

- Deep AI: Unlocking the Future of Artificial Intelligence

- Looka AI: AI-Powered Logo and Brand Design Made Easy

- Machine Customers: The Rise of Non-Human Buyers in the Digital Economy

FAQs

Q1: What is predictive maintenance?

A: It’s a method of using AI and sensor data to predict equipment failures before they happen.

Q2: How do robots help in factory maintenance?

A: Robots inspect equipment, detect faults, and even perform repairs in hard-to-reach or hazardous areas.

Q3: What are the main benefits?

A: Less downtime, lower maintenance costs, safer workplaces, and longer equipment lifespan.

Q4: Are these technologies expensive?

A: While the initial investment can be high, the long-term savings often outweigh the costs.

Q5: Which industries are using this tech?

A: Manufacturing, energy, automotive, chemical processing, and food production industries are leading adopters.